Powering Ventilation, Driving Progress — Achieve Your Mining Goals with MiningFan.

Contact Info

+86 18397234555

No. 001, Nanjiao Town Industrial Park, Zhoucun District, Zibo City, Shandong Province

Mon - Fri, 9am - 5pm

FK Series Auxiliary Axial Mine Forcing Fan is engineered for non-coal mine excavation and localized ventilation, offering single- or two-stage (“II” type) impeller options in a compact, direct-coupled motor-impeller design. Lightweight yet robust, it delivers high efficiency and low noise over distances of 160–1,500 m (up to 2,400 m in series), with fan sizes based on impeller diameter (dm) and a wide range of power ratings. Rated for altitudes ≤ 1,000 m, –10 °C to +35 °C, and ≤ 95 % RH without methane, it reliably supports roadway ventilation, working-face air supply, induced-draft in scraper conveyors, and tunnel or underground engineering applications.

I. Overview

FK Series Auxiliary Axial Mine Forcing Fan (hereinafter referred to as "the fan") features high operating efficiency, low noise, and notable energy savings.

Its design considers the dust and smoke extraction needs, ducted airflow distance, common duct sizes, resistance values, and typical mining conditions for local ventilation. Two structural forms are available: single-stage and dual-stage impellers.

(1) Model Designation

FK Series Auxiliary Axial Mine Forcing Fan

F K №X / Y (Ⅱ)

F: Fan

K: Mine application

№ X: Model No. (impeller diameter, dm)

/ Y: Installed power (kW)

(Ⅱ): Dual-stage impeller; omitted for single-stage

(2) Normal Operating Conditions

a) Altitude ≤ 1000 m

b) Operating temperature: –10°C ~ +35°C

c) Relative humidity: ≤ 95% RH (at +25°C)

d) For underground mine use; air must be methane-free

II. Application

Specially designed for non-coal mines in metallurgy, chemical, building materials, nuclear and similar sectors, this fan serves for drift and stope ventilation, scraper drift air extraction, sublevel caving, other local ventilation, and auxiliary ventilation. It is also suitable for tunnel and underground construction requiring ducted ventilation.

III. Features

High operational efficiency

Full range of models and strong adaptability—varied airflow and pressure combinations, airflow distance from 160 m to 1500 m (over 2400 m with series connection)

Compact size, light weight, easy to move

Direct-coupled motor and impeller for high stability, easy installation and maintenance, low system resistance

Low noise

IV. Structure

The fan uses a direct-coupled motor and impeller design. The main body is welded from steel plates, housing both motor and impeller, for compactness and stability. The assembly includes the inlet collector, impeller, rectifier, guide cover, casing, and motor.

1. Structural Diagram of FK Series Ventilation Fan

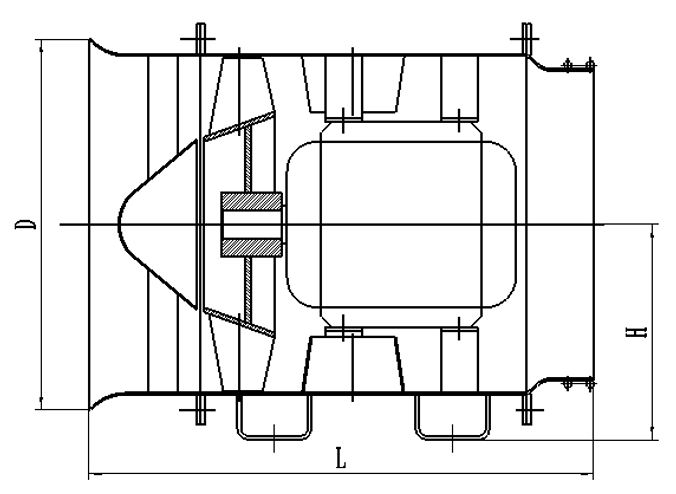

Figure 1: Schematic Diagram of Single-Stage Impeller Auxiliary Fan

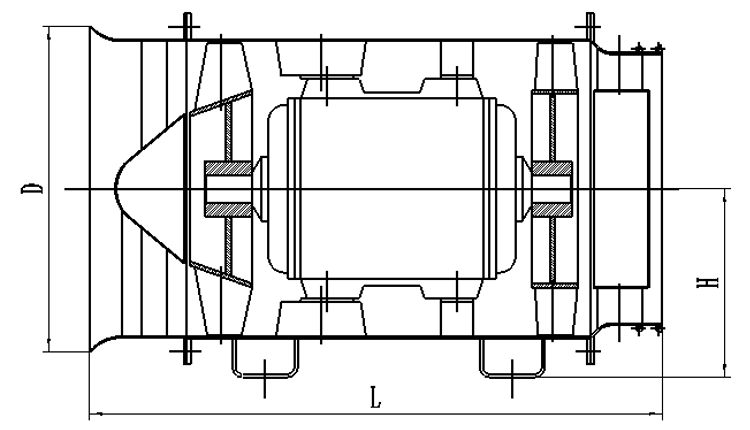

Figure 2: Schematic Diagram of Double-Stage Impeller Auxiliary Fan

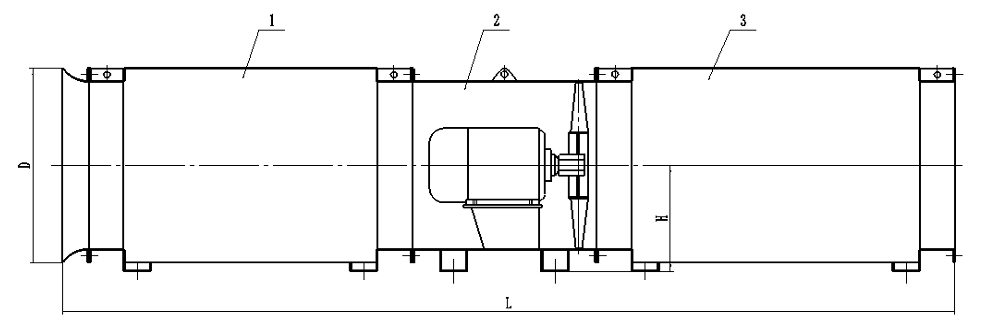

Figure3

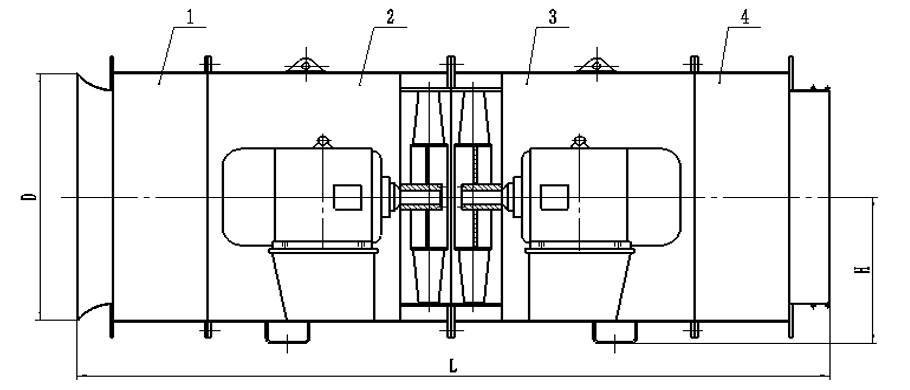

Figure4

Main Technical Parameters Table of FK Series Ventilation Fans

| Model № | Speed r/min | Airflow m³/s | Total Pressure Pa | Rated Power kW | Min. Duct Diameter mm | Max. Efficiency % |

|---|---|---|---|---|---|---|

| 3 | 2840 | 0.9–1.4 | 928–575 | 1.5 | 300 | ≥75 |

| 4.0 | 2840 | 1.4–2.1 | 853–588 | 2.2 | 300 | ≥75 |

| 4.0 | 2880 | 1.5–2.4 | 1263–752 | 3 | 350 | ≥75 |

| 4.0 | 2890 | 2.1–3.4 | 1275–981 | 4 | 400 | ≥75 |

| 4.0 | 2910 | 2.2–3.5 | 1648–1020 | 5.5 | 400 | ≥75 |

| 4.0 | 2937 | 2.2–3.5 | 2923–1811 | 11 | 400 | ≥75 |

| 4.5 | 2910 | 2.6–4.2 | 2256–1177 | 7.5 | 400 | ≥75 |

| 4.5 | 2937 | 3.1–5.0 | 2093–1295 | 11 | 450 | ≥75 |

| 4.5 | 2937 | 3.0–5.2 | 2276–1275 | 11 | 450 | ≥75 |

| 4.5 | 2937 | 2.8–4.3 | 3237–1471 | 11 | 400 | ≥75 |

| 5 | 2937 | 4.2–6.6 | 1726–1324 | 11 | 450 | ≥75 |

| 5.25 | 2940 | 4.0–6.3 | 3776–2648 | 28 | 500 | ≥75 |

| 5.5 | 2910 | 4.3–5.1 | 633–475 | 5.5 | 550 | ≥75 |

| 6.5 | 2937 | 7.1–8.4 | 884–663 | 11 | 650 | ≥75 |

| 7 | 2937 | 8.8–10.5 | 1025–769 | 15 | 700 | ≥75 |

| 7.5 | 2940 | 10.9–12.9 | 1177–883 | 22 | 750 | ≥75 |

| 8 | 2940 | 13.2–15.6 | 1339–1005 | 30 | 800 | ≥75 |

| 5.5 | 2910 | 4.8–5.8 | 1182–515 | 2×5.5 | 550 | ≥75 |

| 6.5 | 2937 | 7.9–9.5 | 1651–719 | 2×11 | 650 | ≥75 |

| 7 | 2937 | 9.9–11.9 | 1915–834 | 2×15 | 700 | ≥75 |

| 7.5 | 2940 | 12.2–14.6 | 2198–957 | 2×22 | 750 | ≥75 |

| 8 | 2940 | 14.8–17.8 | 2501–1089 | 2×30 | 800 | ≥75 |